Our advantages

Complete internal supply chain

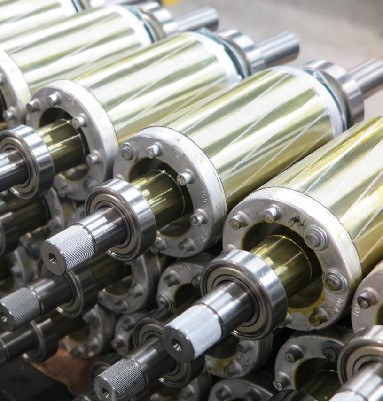

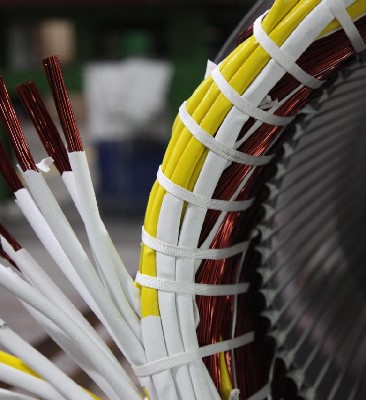

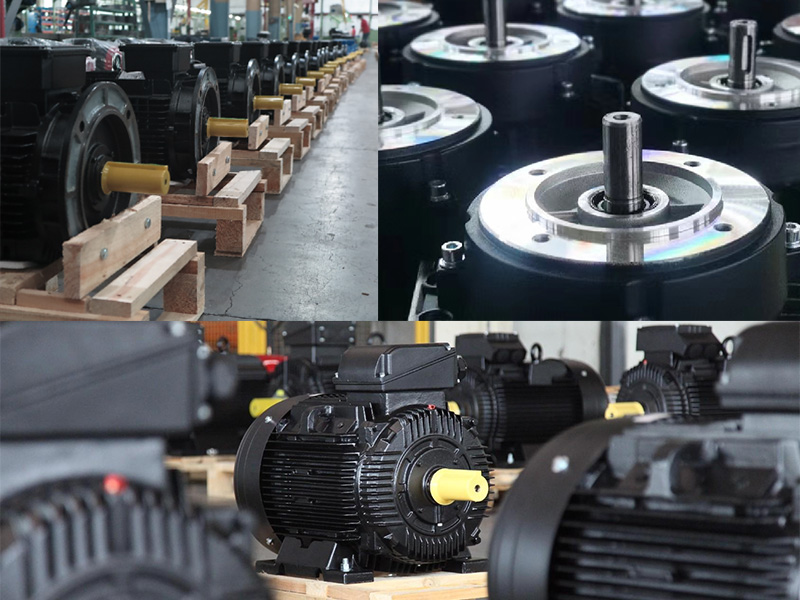

We control every aspect of production, from the smallest components to the final product, which helps us meet the specific market's demand for stable product quality. WONDER has a complete internal supply chain for the motor industry, from casting, metalworking, punching, winding, dipping, painting, assembly to testing, all procedures are completed internally.

Rich product line After years of accumulation, WONDER now has a full range of motor product lines from ordinary energy efficiency to national standard (GB18613-2020) Level 1 energy efficiency (IE5), providing personalized drive solutions that meet various needs. Power range: 0.09kW-1500kW Machine base range: 56-500mm, covering voltage, efficiency, and manufacturing standards of major countries around the world Optional: Various protection levels (IP56/IP66/IP67), special voltage, special frequency, special shaft, special end cap, etc |

Advanced processing equipment

At WONDER, technology is the core competitiveness. We have a large number of modern production equipment and experienced engineers and employees, which enable WONDER to have special process capabilities, such as designing and processing special shafts, special end caps, and casings. In addition, WONDER has rich experience in producing high-temperature motors and variable frequency motors. At the same time, an increasing number of highly artificial intelligence and automation devices have made WONDER's infrastructure at the forefront of the industry.

MAZAK CNC machining center

SCHENK dynamic balancer

FANUC robotic arm

Coordinate measuring instruments, etc

Design and development capability

Design and development capability

Provincial Technology Research and Development Center 41 invention patents and utility model patents in the field of high-efficiency motors We have a team of senior design engineers who can independently develop a full range of motors ranging from ordinary energy efficiency to Level 1 energy efficiency (IE5) Capable of providing analysis reports for all design and production details Cooperate with professional service technology from universities such as Zhejiang University and Fuzhou University Collaborate with top domestic research institutions such as the Haixi Institute of the Chinese Academy of Sciences and the Xi'an Institute of Microelectronics for research and development Annual budget of several million yuan is invested in efficient motor design and research and development work Powerful driving solution design capabilities to meet the usage needs of different customers |